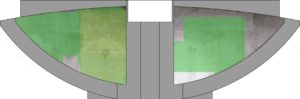

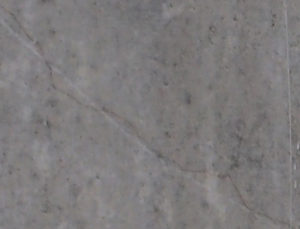

The trimmer joists of the Hyrôme viaduct are made from reinforced concrete. They are 9.60 m long by 3.50 m high by 2.40 m wide. They were formed and cast in place in one single phase. Due to their dimensions and the way they were made, the trimmer joists are considered “massive” and they currently reveal significant cracks. Establishing an exact map of the cracks on the trimmer joists, as part of a classic IDP, proved difficult. ASF therefore requested the use of the DIADES drone in order to obtain a precise map of the defects and to distinguish the levels of cracking according to the LPC n° 47 method.

Client & Project Manager Features

Features

- Number of decks: 2

- Number of spans: 3

- Length of central span: 50 m

- Total length: 130 m

- Width of the track: 11 m

Mission of Diades

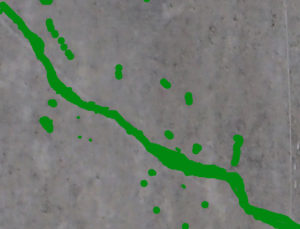

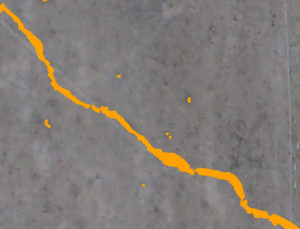

To begin with Diades carried out a drone inspection of the trimmer joists on the Hyrôme viaduct. From a few metres away from the walls, the drone photographed each side of the 4 trimmer joists without any obstruction and without interfering with the use of the structure. Once the information had been obtained on site, it was processed using software programs developed by DIADES, such as DiaMap©, in order to produce a precise map of the defects. These programs enable cracks to be detected automatically. The cracking indices were calculated digitally using the LPC n° 47 methods on the worst areas.

Detection of cracks

Cracks are detected using 3 filters which enable most of the cracks present on the photographed surface to be detected.